Thorough Examination Guide

Thorough Examination: A Guide

Beware: not every Examination is truly Thorough. CFTS is a national standard guaranteed to fulfil your obligations under LOLER 98 and PUWER 98.

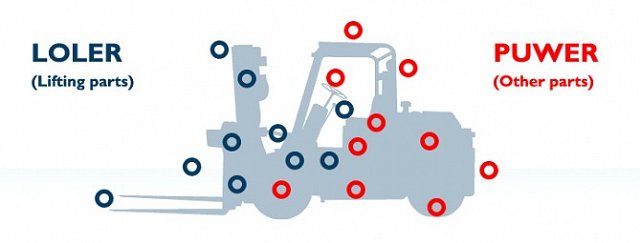

Some so-called “Thorough” Examinations only cover a fork truck’s lifting mechanism, doing the minimum to meet LOLER 98 (in blue, in the picture); but you also have a duty under PUWER 98 to ensure equipment is safe to use – and that requires a much more detailed examination (also including the items in red). A CFTS Thorough Examination is certain to cover both parts.

The video on this page explains the difference and what you should expect from a Thorough Examination.

Below we have listed what a truly Thorough Examination should include.

Mast

The mast must be inspected throughout its full range of extension and movement, to ensure smooth, safe operation and structural integrity. The same applies to the boom on a telehandler.

Hydraulic Systems

The hydraulic check is a major task, covering all hoses, pipes, cylinders and reservoir along with a prolonged load test to rule out unacceptable descent. Filters are also inspected, for any signs of debris.

Forks

Fork arms are subject to constant abrasion and stress making them particularly vunerable. They must be of the correct capacity, meet ISO 5057 for wear, and must not be cracked, deformed or damaged. Fork location and end stops are also checked.

Traction System

The prime mover and transmission are inspected. On diesel and LPG trucks this extends to the exhaust system and emission levels, to ensure safe operation indoors. On electric trucks, the battery and connections are checked. *may not be checked in a non-CFTS examination*

Rating Plate

Clear rating information is absolutely essensial to the safe operation of any forklift truck. The plate must be clear, securely attatched and updated to take accounts of any attachment or side shift fitted.

Structural Fastenings

Important structural fastening components, such as those holding axles, fluid reservoirs and batteries, must be secure and undamaged. *may not be checked in a non-CFTS examination*

Brakes

Brake failure is a forklift truck operator’s worst nightmare, but brakes are left unchecked in most examinations. A CFTS thorough examination coves both sevice and parking brakes, checking all hydraulics, pneumatics, mountings, pedals, levers and linkages to ensure the brakes operate exactly as expected. * may not be checked in a non CFTS examination

Chains

Lift chain failure is potentially lethal, but the wear, elongation or corrosion that can cause it it are gradual, and tricky to spot: a change of just 2% is a cause for concern. Chains must therefore be checked carefully, in at least three places, along with anchors and pulleys.

Controls

As well as the controls themselves, which must all be fully functional, securely mounted and clearly marked, all linkages and cables must be inspected to prevent potential failure through damage, corrosion or wear.

Steering

To ensure the truck can be operated safely, all mechanical and hydraulic steering parts are inspected for signs of failure, corrosion, damage or excessive wear. Proper steering response is confirmed by manoeuvring the truck at low speed. *may not be checked in a non-CFTS examination*

Safety Systems

Safety systems can only protect workers if they operate correctly. Moreover, because operators come to depend on them, any failure can instantly cause serious unsafe practices.Any audible alarms and visible warnings are checked, along with interlocks and seat switches if present. Capacity and data plates must also be present, secure and easy to read.

Chasis

The chassis is inspected for cracking and signs of damage, with particular attention paid to the welds.*may not be checked in a non-CFTS examination*

Seat Mounting

The seat mounting must be absolutely secure, along with the panel where it is attached.Any anti-vibration mechanism is also checked for signs of damage.*may not be checked in a non-CFTS examination*

Seat Restraint

Any operator restraint including seat belts and any other devices designed to keep the operator safely seated in the event of a tipping accident – is checked to ensure it is fully functional and free from damage. *may not be checked in a non-CFTS examination*

Attachment/ Side-Shift (If Present)

Any attachment or sideshift must operate smoothly and safely throughout the full range of its movement. It should be mounted securely and free from damage, distorton and cracks.

Tilt Mechanism

To enable safe operation, the tilt must move in an even, controlled way. It must also be checked for damage and scoring, which can indicate more serious issues.

Load Guard

Must be structurally sound and securely mounted otherwise it may not only cause falling loads, but become a hazard in its own right.

Carraige

The Fork arm carrier must be free from distortion or cracking, and any load rest extension must be sound and properly mounted

OVERHEAD GUARD/ CAB

As well as compromising protection from falling loads, a damaged overhead guard or cab can be a clue to potentially lethal structural problems. The cab or guard must therefore be sound and securely mounted.Any transparent screens must be clear and undamaged to ensure optimum visibility. *may not be checked in a non-CFTS examination*

Counter Weight

Often a cast iron block of two tonnes or more, the counter weight suddenly coming loose can be catastrophic – both to truck stability and as a hazard in its own right.All fastenings must therefore be safe, secure and undamaged. *may not be checked in a non-CFTS examination*

Wheels & Tyres

Because of the forces involved, wheel failure not only causes accidents but can be a fatal hazard in its own right. Wheels and their assemblies should be in sound condition and securely fixed. Tyres must be checked for specification, wear, damage and bonding failure. Composite wheels and tyres must be a correct combination, suitable for the application and truck. Wheel bearings also need particular attention. *may not be checked in a non CFTS examination*

Why CFTS?

Since 2004, CFTS has been the fork lift truck industry’s own adopted standard for Thorough Examination.

Created by the major trade associations – in close consultation with HSE – to solve a vital problem facing lift truck users.

Imagine there was no national standard for your car’s regular MOT test.

Rival garages deciding for themselves what needs to be checked – pricing their inspections accordingly, with every incentive to cut corners. No consistency. No standards. A confusing mess. What confidence could you have that your car was really legal… or even safe?

This nightmare situation is very much like the real problem that faced fork lift truck users until 2004, and the creation of CFTS.

PUWER and LOLER regulations legally require all lift trucks to have a valid Certificate of Thorough Examination – but with precious little official guidance about what this should cover.

To provide clarity, the industry’s major trade associations worked together – in consultation with the Health and Safety Executive – to give clear, definitive procedures and consistent, high national standards for a safe and genuine Thorough Examination.

The result is Consolidated Fork Truck Services (CFTS): the national accreditation scheme for Thorough Examination, specifically for companies who service fork lift trucks.

Look for the distinctive CFTS mark: it’s your guarantee that a Thorough Examination is full and valid under law, and will be carried out by a fully trained engineer in accordance with strict quality procedures.

Without it, your certificate may not be worth the paper it’s printed on.

Pricing

| Scissor Lift Tables | From £40.00 |

| Semi / Fully Powered Pallet Trucks | From £40.00 |

| Perdestrian Powered Stacker Trucks | From £55.00 |

| Reach Trucks / Electric Counter Balance Trucks | From £72.50 |

| LPG/Diesel Powered Forklift Trucks | From £79.50 |

The above prices exclude Site Callout fees.